Premium Building Material Lvt/Spc/PVC/Rubber/Ceramic/Porcelain Plastichybrid Luxury Vinyl Flooring Plank Tile

Description

Basic Info.

| Model NO. | YH33011-03 |

| Lead Hardness | Hard |

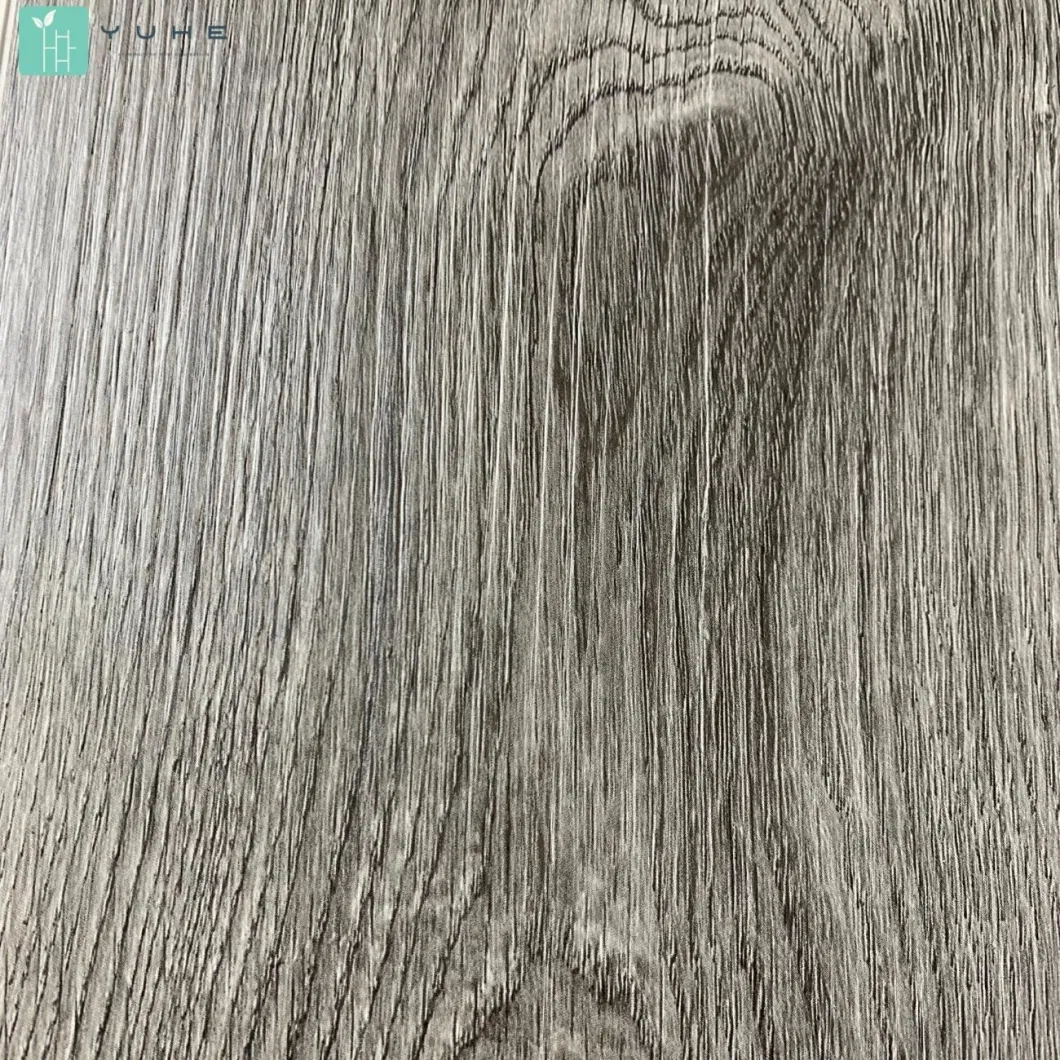

| Surface Treatment | Deep Embossed |

| Pattern | Wood Grain |

| Color | Multi-Color |

| Usage | Household, Commercial |

| Building Material | Hotels Shopping Mall Hospital School |

| Laminated Flooring | Good for High Traffic Area |

| Wear Layer | 0.3mm 0.5mm 0.7mm |

| Size | 150X1220mm, 180X1220mm, 228X1220mm, 228X1524mm |

| Engineered Flooring | Real Wood Bevel Available |

| Lvt Floor | Antique Wood Texture |

| Lvt Dry Back | First Choice for DIY |

| Vinyl Tile | Anti-Bacterial |

| Vinyl Floor | 100% Waterproof |

| Transport Package | by Sea |

| Specification | 1220*228mm |

| Trademark | Yuhe |

| Origin | China |

Product Description

Color | Grey, Yellow, Brown |

|---|---|

| Size | 150x1220mm, 180x1220mm, 228x1220mm, 228x1524mm |

| Thickness | 4.0mm, 5.5mm, 6.0mm, 7.0mm |

| Finish | Standard UV Coating, Ceramic Coating, Antibacterial Coating |

| Texture | Granite, Slate, Deep Embossed, EIR, Crystal |

| Wear Layer | 8mil, 12mil, 20mil |

| Installation | Click System |

| Underlayment | Optional (EVA, IXPE, Cork) |

SPC Floor Manufacturing Process:

Nowadays, SPC flooring is becoming more and more popular and it is gradually replacing many of the floors we used before, such as LVT CLICK Flooring, and WPC Flooring. Let's take a look at the production process of SPC flooring.

Step One: Mixing and Heating

Put Raw material (PVC resin powder, stone powder, plasticizer, stabilizer, carbon black, etc) together, Using 100% virgin material

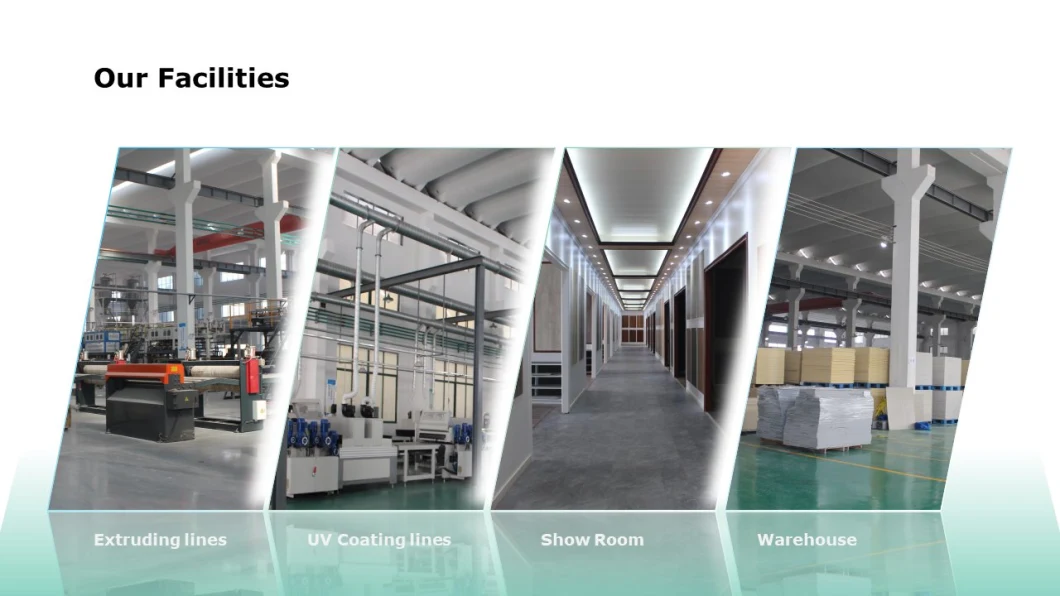

Step Two: Extruding

Semi-finished plank (rigid core) to settle basic thickness

Step Three: Hot pressing

Press Wear layer + Decor films (Texture and peeling strength)+ Semi-Finished plank together

Step Four: Cutting

Whole plank (High efficiency & accuracy) into pieces, the size can meet different kinds of requests

Step Five: UV Coating

Make surface resistant & durable for scratch and stain, we have ceramic bead coating, diamond coating, and easy cleaning coating (just using water can clean the dirty place made by color pen) for choice

Step Six: Standing time

To make SPC more stable, each process under hot temperature will be standing, following the international EN standard

Step Seven: Slotting and Grooving

Make click system easy to install, our staff have over 10-years -experience grooving technique

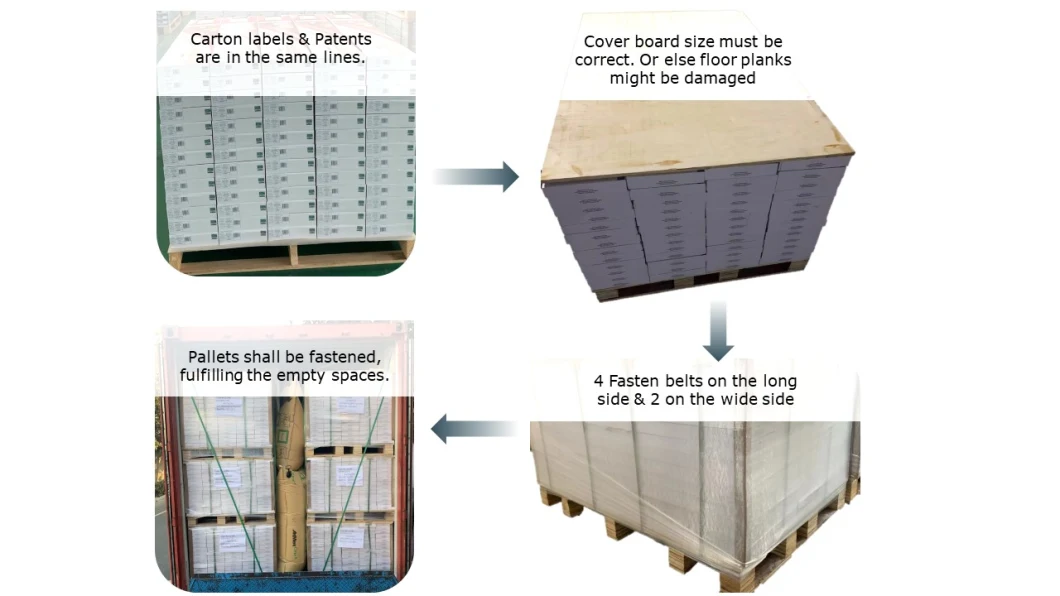

Step Eight: Inspection & Packaging & Warehousing

Our Contact